Fuel from the Fields: Charcoal from agricultural waste

Practical Action

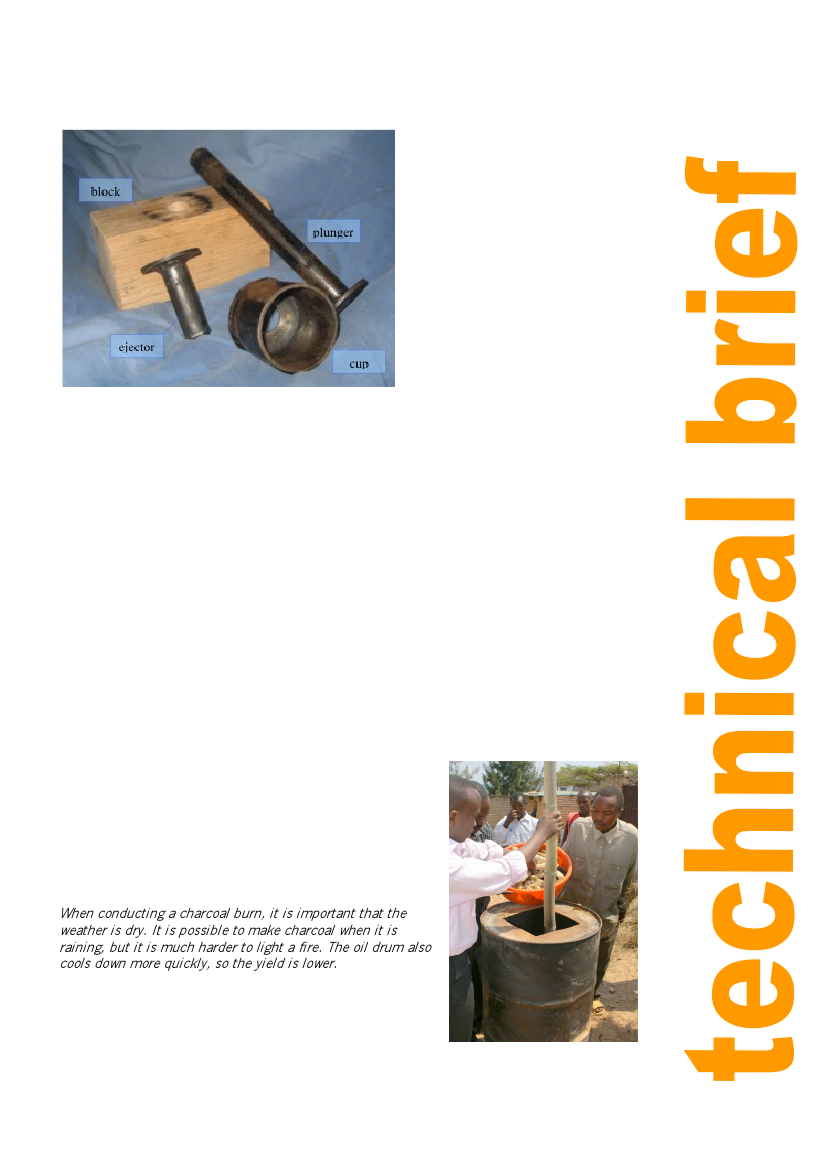

Figure 6: Parts of the briquette

press. Photo credit: Fuel from the

Fields.

• The cup is made from a large, hollow pipe, with sheet metal welded to the bottom. The

bottom should have a hole drilled in the centre, wider in diameter than the ejector pin.

• Cut two sheet metal discs, slightly smaller in diameter than the inside of the cup. These

form the ejector and plunger plates.

• To make the ejector, weld the ejector plate to a short length of pipe. The ejector should

be as tall as the cup. When using the briquette press, the bottom of the pin is pushed on

the surface of the hammering station, to eject the briquette. If the ejector is as tall as

the cup, the briquette is ejected completely, and the ejector pin stays in the hole at the

bottom of the cup.

• To make the plunger, weld the plunger plate to a length of pipe.

• The hammering station is made by drilling a hole into a table or block of wood. The hole

must be larger in diameter and length than the ejector pin, but smaller than the diameter

of the cup. This allows the base of the cup to rest flat on the surface of the table, with

the ejector pin dropping through the hole, while the press is in use.

Making charcoal

The process of charcoal production is as much an art as a

science. It requires experience to produce high quality

charcoal, and to get high yields of charcoal from an oil drum.

The method must also be adapted slightly for different

materials. Whilst this guide provides approximate details, the

time required at each stage is variable; there is no substitute

for experience.

When conducting a charcoal burn, it is important that the

weather is dry. It is possible to make charcoal when it is

raining, but it is much harder to light a fire. The oil drum also

cools down more quickly, so the yield is lower.

Filling the drum

When filling the drum, it is necessary to allow air to flow

through the drum so that the fire can burn hotly and evenly

and produce high quality charcoal.

Figure 7: Fill the drum with

a central chimney. Photo

credit: Fuel from the Fields.

4